Thermostatic Expansion Valve Response

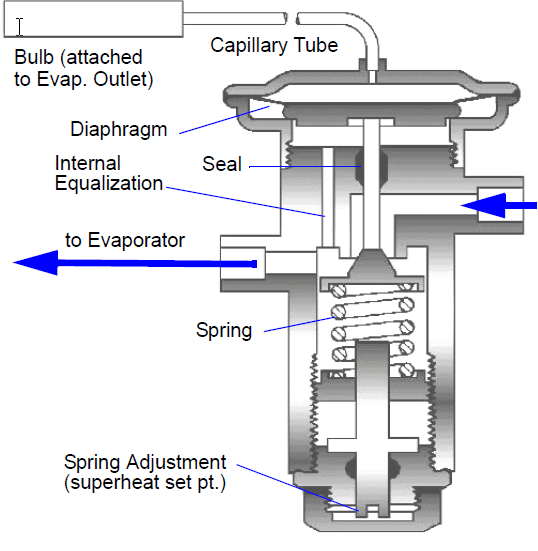

Thermostatic expansion valves (TXVs, also called TEVs) are often used in vapor compression based refrigeration and air conditioning systems. These valves adjust to allow more or less flow to achieve complete vaporization with adequate (but not excessive) superheat at the outlet of the evaporator.

TXVs “sense” the differential in temperature between the inlet and outlet of an evaporator. Unfortunately, there is a lag between the sensing of this temperature and its adjustment. Thermal Desktop and FloCAD can be used to analyze the dynamic stability of a TXV-controlled system: its ability to hold a set point after perturbations and to provide the necessary superheat.

For example, assume that there is currently too much superheat being produced, such that the TXV begins to open. In addition to lags and finite time constants in the sensing mechanism and valve pin motion, the newly released fluid must traverse the length of the evaporator, quenching heated sections as it does. By the time cooler vapor reaches the outlet, the system may overshoot and “hunt” for a stable set point. This difficulty in arriving at a stable set point is therefore termed evaporator or TXV “hunting.” Many time constants and lags are involved, making detailed modeling necessary. Hunting is undesirable not only from an efficiency viewpoint, but also because it leads to increased wear and tear of the valve and compressor.

Key to this analysis is the ability to calculate the forces on the TXV valve pin. These forces include not only the pressure difference across the diaphragm, but also the spring force and the frictional force. Inertia of the pin is also important. The ordinary differential equation (ODE) solvers allow you to define the equation of motion to be co-solved along with the thermohydraulic model to define the pin location. Once the pin position is known, the corresponding resistance of the TXV can be interpolated from the provided table of mass flow rate versus delta pressure.

The charts below show the resulting valve pin position and key temperature responses of such and analysis.

Further details of the analysis can be found in the CRTech User Forum.

See also this example of a wax actuator in a three-way mixing valve.