“Material Flow” or Advection

Thermal Desktop® is capable of modeling steady and unsteady heat transfer problems for both moving and stationary parts, including conduction, convection, contact, and thermal radiation.

When a batch process is to be simulated, or when discrete parts move (such as ingots through a furnace, or ground-tracking antennae on satellites), the part itself can be translated or rotated within a transient solution. But when the motion is continuous, such that a steady-state solution is possible, different modeling methods are available.

Examples of such continuous motion include a sheet of glass solidifying as it is lowered through a temperature-controlled zone, a gypsum board moving through a dryer, and a conveyor belt carrying baked goods through a continuous oven. In those circumstances, you can build a fixed model of the both stationary parts (heat lamps, ovens, driers, and so forth) and the moving parts (rollers, sheets, belts, etc.). Then you can superimpose an advection or “material flow” term on the rotating or translating parts.

For example, below is an open mesh conveyor belt with rollers moving under three heat lamps (using collimated rays for illustration purposes). Ray plots have been superimposed to show the lamp rays passing through the semi-transparent mesh belt, losing energy as they pass through each layer.

A key feature of the Thermal Desktop advection tools is that you can analyze moving parts using fast-to-solve steady states. In the above case the belt is moving at 0.1 ft/s. In this video, the belt is surging between zero and 1 ft/s, making the numerical motion of the belt more obvious.

Example applications for this capability include:

- Belt conveyor furnaces, conveyor ovens

- Steel and aluminum sheet metal manufacturing

- Glass making (especially plate glass)

- Paper making, fiber products, particle board and flakeboard drying and curing, drywall (wallboard) manufacturing

- Optical fiber manufacturing (drawing fiber optic cable through a furnace)

- Pebble bed reactors

- Coke furnaces

- Rotary furnaces

- Carbon foam and metal foam heat exchangers, geothermal storage systems

- Rotating disk heat exchangers and dehumidifiers

- Moving belt heat exchangers, moving belt radiators

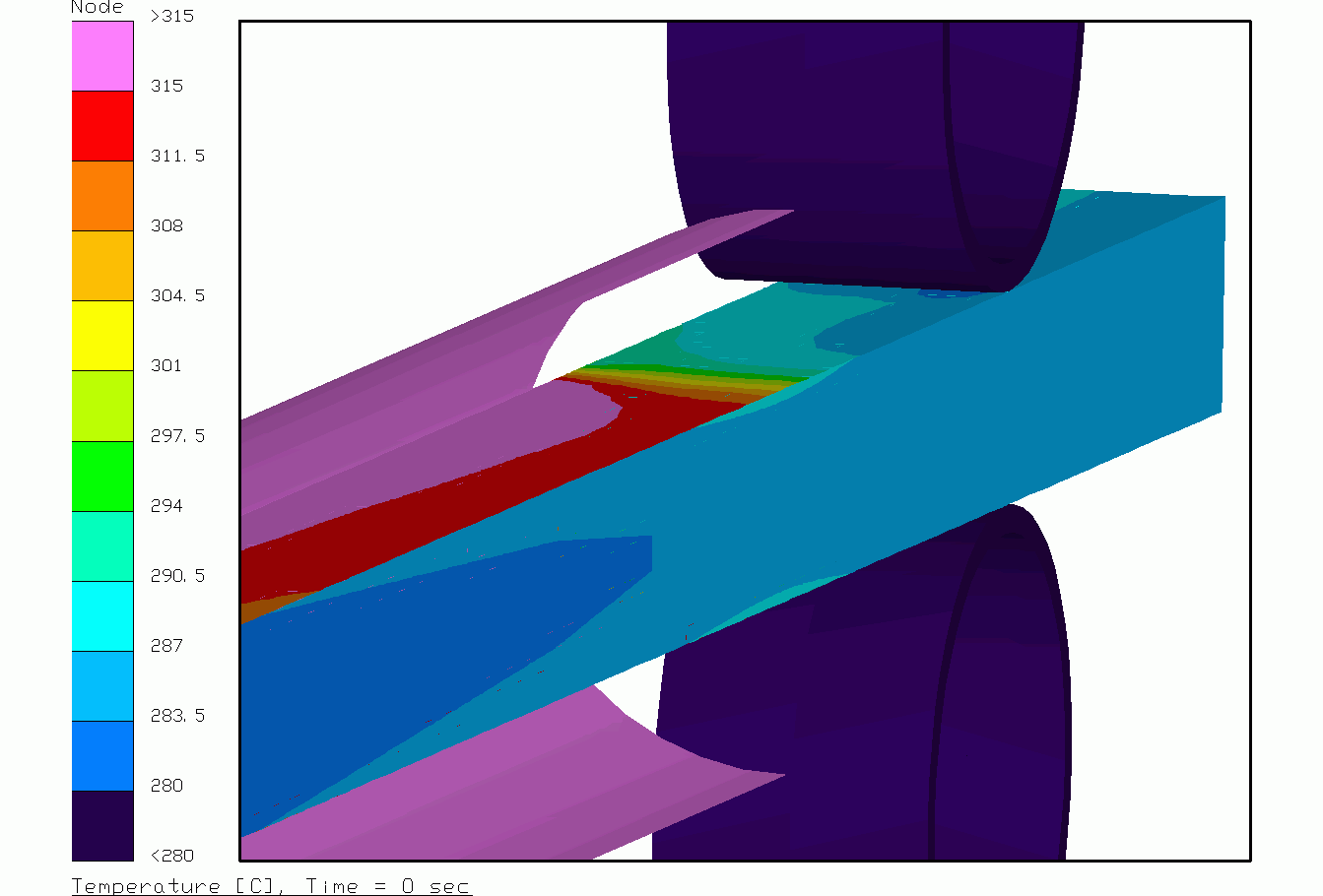

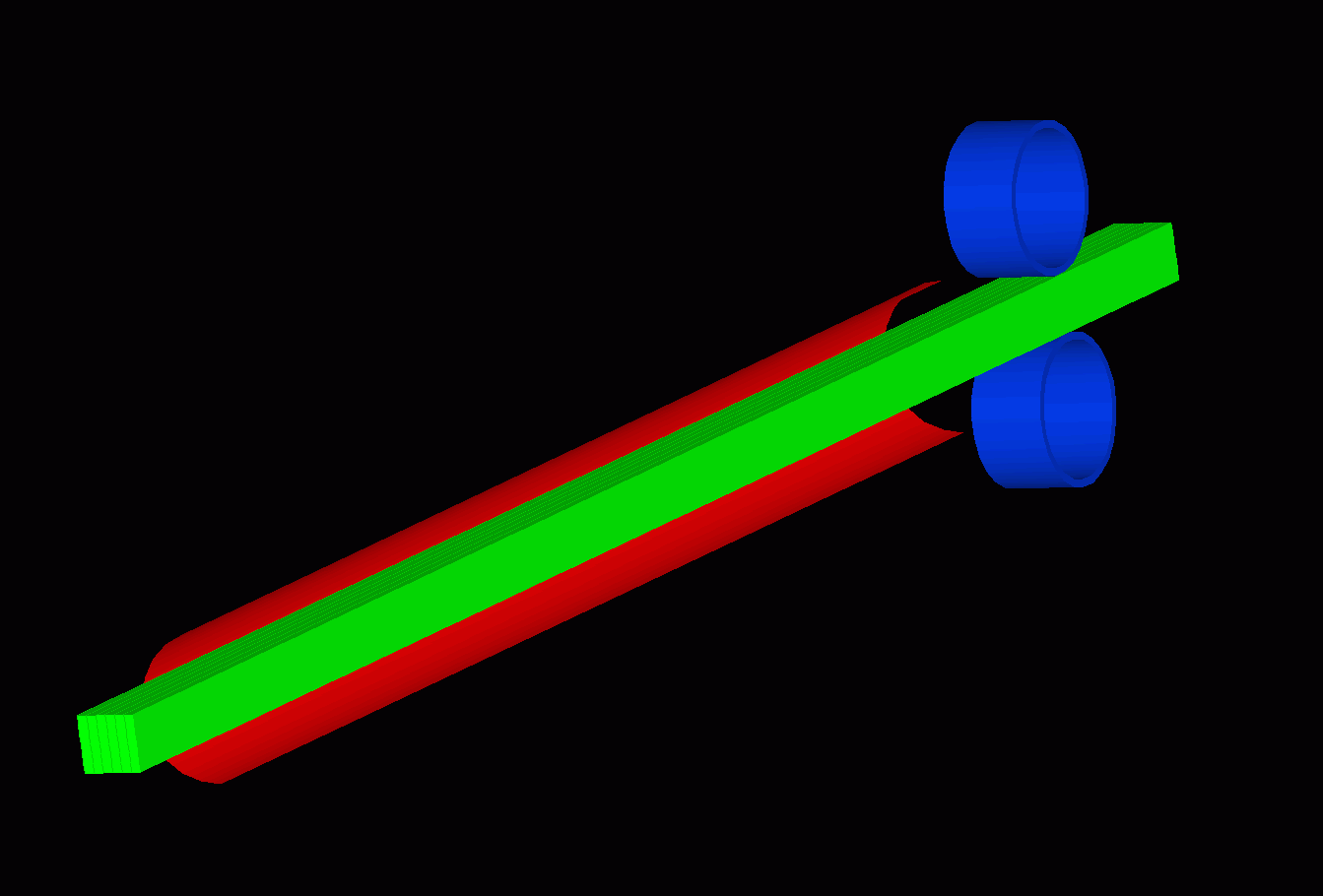

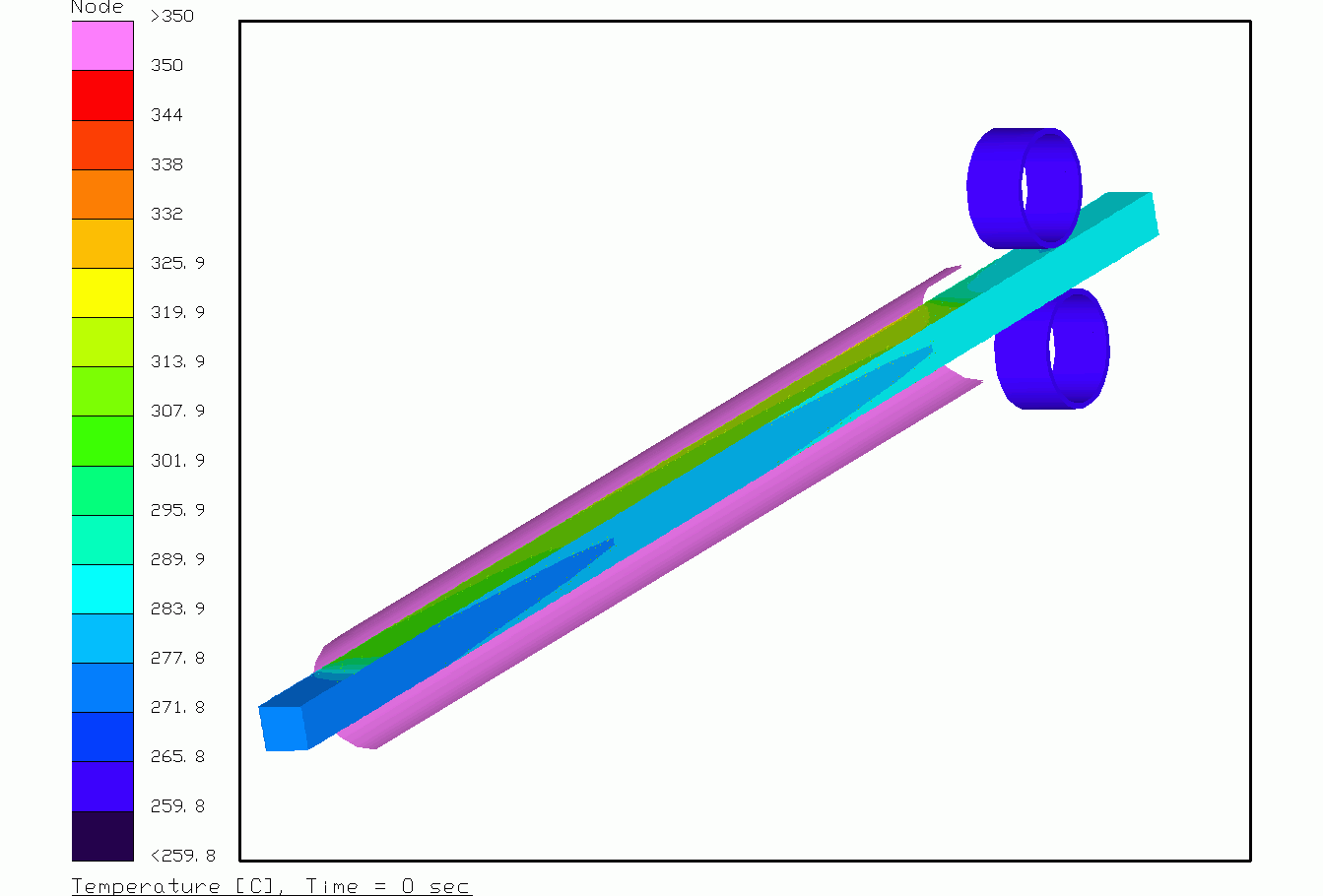

Hot Wire: Material Flow Example

A large rectangular copper “wire” passes through a continuous-flow tubular furnace used to harden a thermoset polymer coating. A pair of cooled rollers at the exit of the furnace help to both position the wire and smooth the coating.

Click here to download the hot wire sample model from our forum.

.png)