Line Chilldown Using Liquid Hydrogen and Liquid Nitrogen

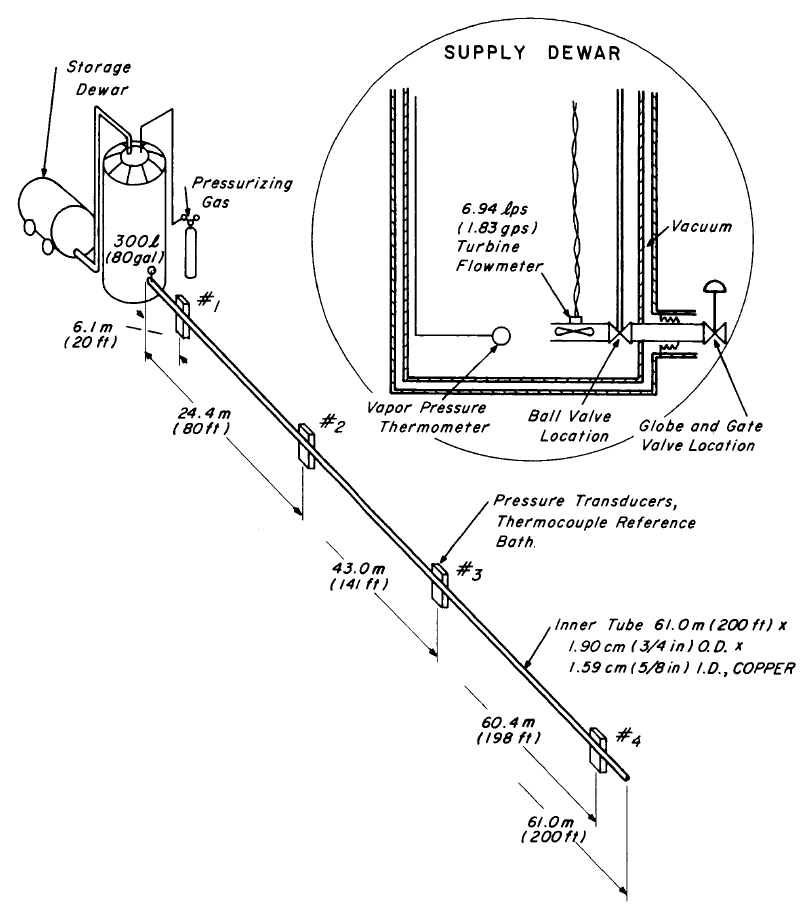

This validation case compares SINDA/FLUINT and FloCAD® predictions with a 1966 test by the National Bureau of Standards (NBS, now National Institute of Standards and Technology, NIST). In the NBS tests, a pressurized dewar containing either LN2 or LH2 was isolated from an empty 200ft (61m) line (open to the atmosphere) by a valve. At time zero, the valve between the dewar and the line was opened, and cryogenic liquid was allowed to flow until the line was completely full and liquid was discharged from open end of the pipe.

Comparison with Test Data

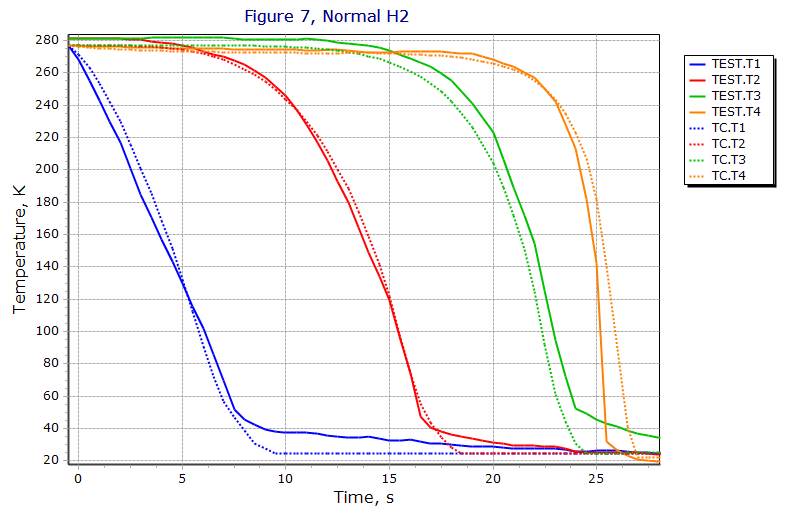

Differences between parahydrogen and normal hydrogen are explored, since the exact composition of the hydrogen is unknown. The importance of uncertainties in heat transfer and pressure drop correlations, copper alloy properties (also unknown), dewar pressure, and even the roughness and manufacturing tolerance of the tubing is explored. This study demonstrates automated calibration to test data, and investigation of sensitivities.

Click here to fetch the Cryogenic Cooldown Validation from our User Forum