Modeling Solar Concentrating Systems in Thermal Desktop

C&R Thermal Desktop®, CRTech TD Direct®, RadCAD®, and SINDA/FLUINT offers best-in-class thermal radiation solutions, which are critically important to both space vehicle and solar power system analyses. This tool suite also uniquely offers single- and two-phase thermohydraulics, which means an entire solar thermal energy system can be modeled from the collectors to the steam power cycle or feedwater heat exchangers.

The latter strategy was recently implemented near Grand Junction, Colorado by Xcel Energy. In that system, a parabolic trough system is used to preheat feedwater to a coal burning power plant, thereby reducing the amount of coal required.

Paraboloids and Parabolic Troughs

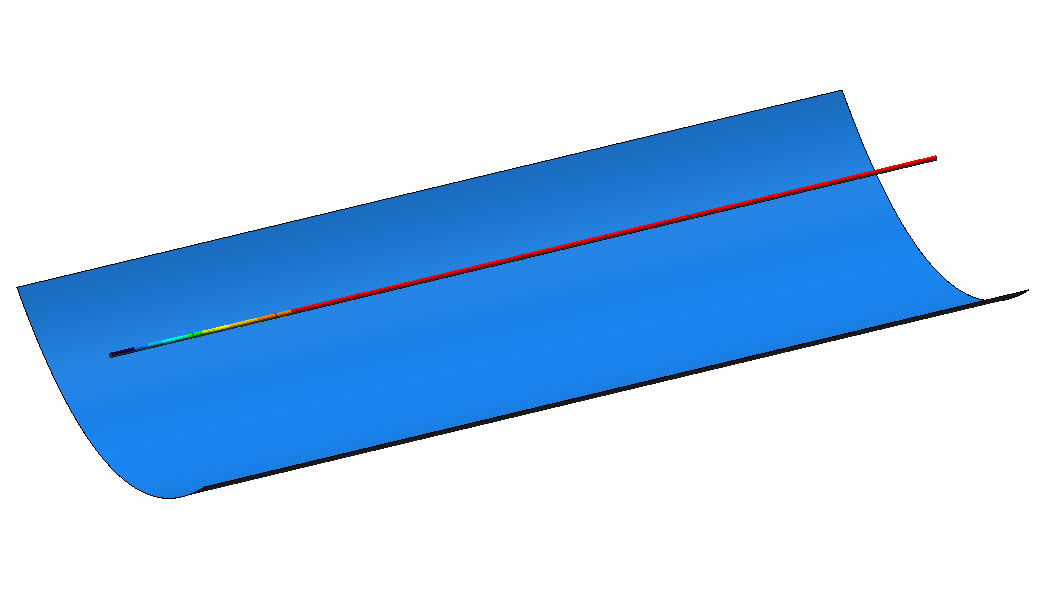

Many solar concentrators are paraboloids, offset paraboloids, or parabolic troughs, as pictured below. These shapes are included in Thermal Desktop as parametric objects. Parametric objects are predefined shapes that can be easily changed by changing a few values. More importantly, parametric shapes have the correct shape regardless of discretization. This fits the idea of thermal-centric: discretize for the solution and not for the shape.

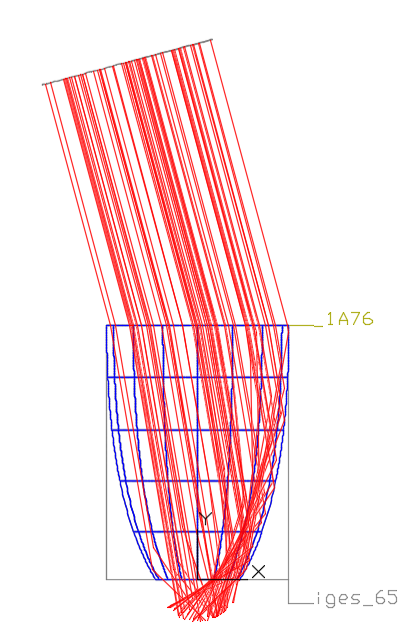

Arbitrary shapes with curved elements

Parametric shapes work well for some systems, but a reflector's shape may be not be well represented by the predefined shapes. An example is a compound parabolic concentrator (CPC), or Winston cone. A CPC is an axisymmetric body formed by rotating a parabolic section about an axis such that any light that enters within the designed acceptance angle is captured at the base of the body. Curved mesh elements can be generated by TD Direct to accurately represent just about any shape of reflector with fewer nodes than possible with flat finite elements.

Additional Thermal Desktop, RadCAD, and FloCAD Capabilities for Concentrating Solar Power Systems

- Accurate curved surfaces for radiation calculations

- Transparent surfaces and solids with refraction

- Mapping of thermal results to structural models

- Receiver pipe

- HCE supports

- Parameterized analyses

- External convection to ambient

- Internal convection between receiver pipe and glass envelope

- Optical properties of the reflector and receiver

- Free molecular heat transfer for near-vacuum in glass envelope

- Diffuse solar load and diffuse sky IR radiation

- Solar tracking for surfaces or groups of objects

- Psychrometrics for condensing air heat exchangers

- Condenser, evaporator, and boiler sizing and simulation

- Phase change materials for thermal energy storage

- Turbomachine components

- Cycle-level analysis of power generation cycles

- Performance map-based descriptions of single- or multi-stage turbomachines

- Steam turbines

- Heat transfer fluid pumps

These capabilities may be used separately for component-level analyses or together for plant-level analyses.