Joule-Thomson Design and Analysis

CRTech tools are used to model the complexities of Joule-Thomson or JT cooling systems, as either blow-down systems or closed cycles (e.g, Linde-Hampson). Because they provide compact and vibration-free cold heads, such coolers are popular for cooling of sensors and electronics including cryogenic and MEMS (microcooling) applications.

The combination of SINDA/FLUINT plus FloCAD® (an optional Thermal Desktop® module) can be used for detailed modeling, system-level modeling, and sizing and sensitivity analyses of cold heads and other heat exchangers.

Key features relevant for analyzing JT cooling systems include:

- Real-gas and saturation dome properties readily available for the most commonly used fluids including hydrogen, helium, nitrogen, argon, CO2, methane, and propane. Additional and custom fluids (e.g., mixed gas coolers) descriptions can be created by CRTech or the user.

- System-level heat exchangers (e.g., NTU, UAtot, effectiveness) for sizing (e.g., set an outlet temperature) and for high-level simulations

- Complex heat exchangers in cold heads and in multi-stage coolers (regenerators, recuperators, intercoolers)

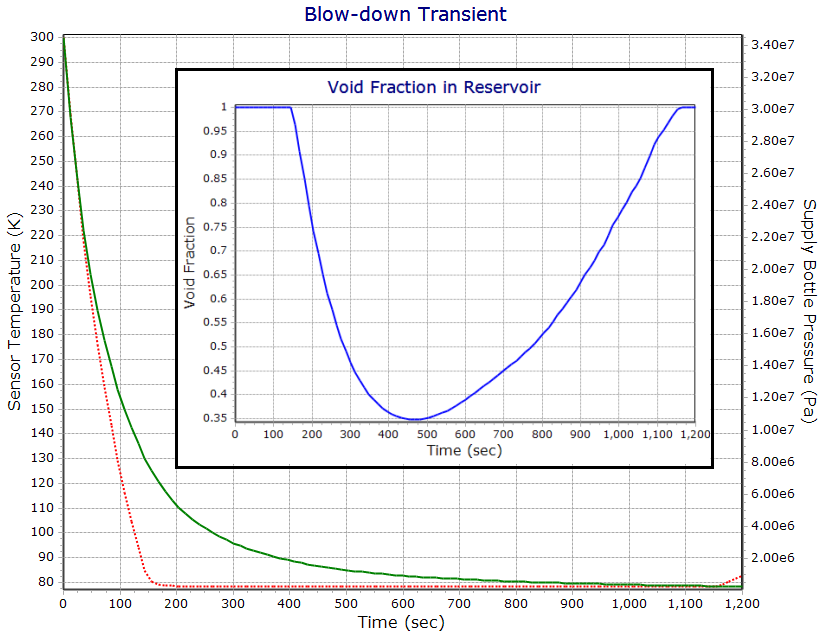

- Transient analyses including tank blow-down and structural cool down

- Expansion into the dome including two-phase heat exchange. See also Two-phase Flow Analysis.

- Arbitrarily complex control systems (PID etc.) applied to valves, compressors, etc.

- Access to parametric modeling and Advanced Design Modules (optimization and sizing, automated model calibration to test data, reliability and statistical design, etc.)

Sample Model of a JT Cold Finger

A sample model is available to illustrate the application of SINDA/FLUINT and Thermal Desktop/FloCAD to the modeling of the Joule-Thomson cycle. These examples demonstrate:

- JT cryostat analysis

- Design optimization and dynamic blow-down (chilldown) analysis

- Modeling of labyrinth seals (even though they purposely leak in this application)

- Modeling of heat exchangers, at both the system and detailed levels

- Including application of compact heat exchanger (CHX) methodology

- Use of FloCAD for both sketch-pad modeling and for geometric modeling using a spiral coil

The models with documentation are available for download.

Click here to fetch the JT Modeling Example from our User Forum