Variable and Fixed Conductance Heat Pipes

CRTech's tools have been validated many times for the modeling of constant conductance (CCHP or FCHP) and variable conductance heat pipes (VCHP), along with other specialized pipes such as diode heat pipes. The methods used are fully capable of accurately capturing the effects of a heat pipe on the host system without allowing the model to get bogged down in the hydrodynamics internal to the heat pipe. These methods have been considered an industry standard since the 1970s and have been validated many times over.

CRTech's tools have been validated many times for the modeling of constant conductance (CCHP or FCHP) and variable conductance heat pipes (VCHP), along with other specialized pipes such as diode heat pipes. The methods used are fully capable of accurately capturing the effects of a heat pipe on the host system without allowing the model to get bogged down in the hydrodynamics internal to the heat pipe. These methods have been considered an industry standard since the 1970s and have been validated many times over.

How Not to Model a Heat Pipe

A common “trick” is to model a heat pipe as a bar of highly conductive material. However, that method has many drawbacks.

- It does not simulate a heat pipe’s length-independent resistance

- It does not account for differences in film coefficients between vaporization and condensation

- It can be disruptive to numerical solutions and potentially cause instabilities in a model

- It does not provide information on the power-length product (QLeff) for comparison against vendor-supplied heat pipe capacity

- It cannot be extended to include the effects of noncondensible gas (NCG)

Another misconception is that heat pipes, being two-phase capillary devices, require detailed two-phase thermohydraulic solutions. While methods exist to model such details, such an approach would represent computational overkill in almost all cases: even heat pipe vendors use simpler calculations when designing heat pipes.

How to Model a Heat Pipe

Heat pipe routines built into SINDA/FLUINT provide fast system-level solutions to modeling heat pipes when a full two-phase solution is not required. Both constant conductance (CCHP, also called FCHP), with or without noncondensible gas (NCG), and variable conductance (VCHP) pipes can easily be simulated. These routines were written specifically to co-solve wall temperatures and gas-front locations, resulting in a more robust tool. The methods used in the built-in subroutines are based on the following recommended modeling methods.

Download a brief explanation on heat pipes are modeled in CRTech products.

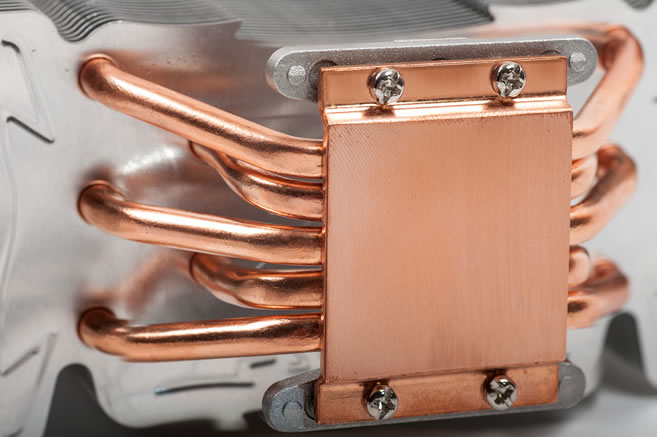

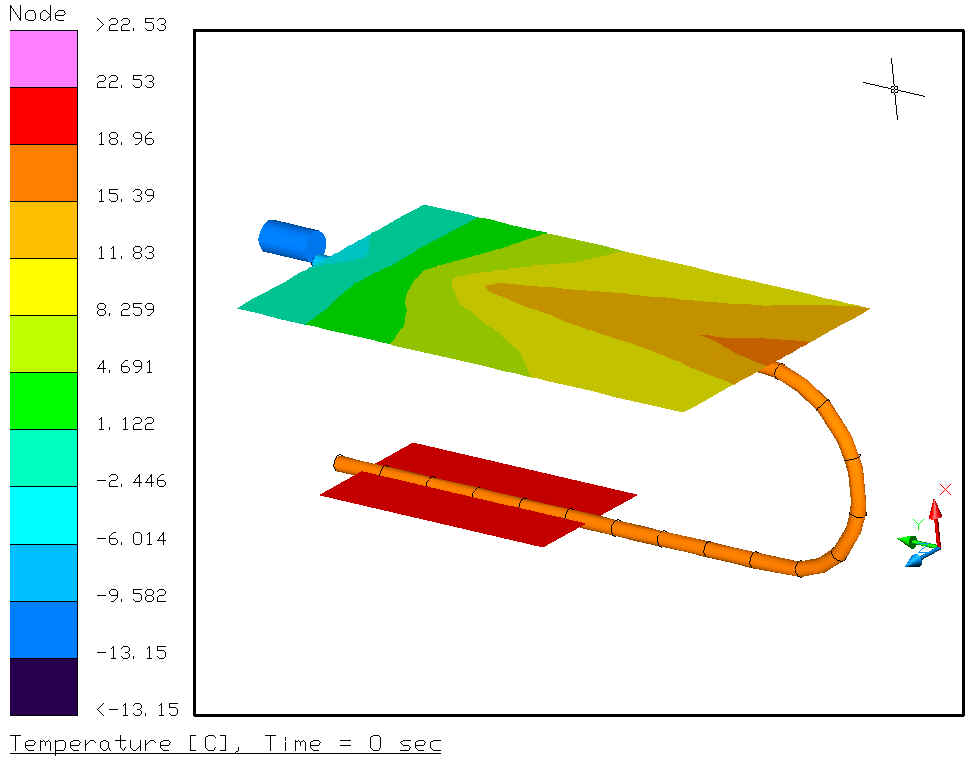

FloCAD®, a Thermal Desktop® module, provides a unique tool for modeling heat pipes within a CAD-based environment. Complex geometries and large networks of heat pipes, can easily be generated.

Features for Modeling Heat Pipes

- Constant (fixed) conductance heat pipes (CCHP, FCHP) and vapor chamber fins

- 1D or 2D thermal model (axial, axial and circumferential, rectangular)

- Distinct vaporization and condensation coefficients for grooved designs

- Prediction of QLeff (power-length product)

- Optional inclusion of noncondensible gas (NCG) degradation

- Fast and easy geometric model generation using FloCAD, including bonding or contact to thermal surfaces and solids and even to other heat pipes

- Additional features for variable conductance heat pipes (VCHP)

- Choose working fluid from library or define a new fluid

- Perfect gas or real gas descriptions for control gas

- Fast and stable 1D (flat front) gas blocking algorithm

- Warnings for erroneous designs, gas charges, environments

Sample Applications

- Deployable two-phase radiator systems for aerospace applications

- Electronic cooling systems

- De-icing applications

- Isothermal furnace liners

- Heatpipe heat exchangers

Supporting Resources

A free online webinar on this topic is available: Modeling Heatpipes in FloCAD

Publications

- CAD-based Methods for Thermal Modeling of Coolant Loops and Heat Pipes

- Adding Heat Pipes and Coolant Loop Models to Finite Element and/or Finite difference Thermal/Structural Models