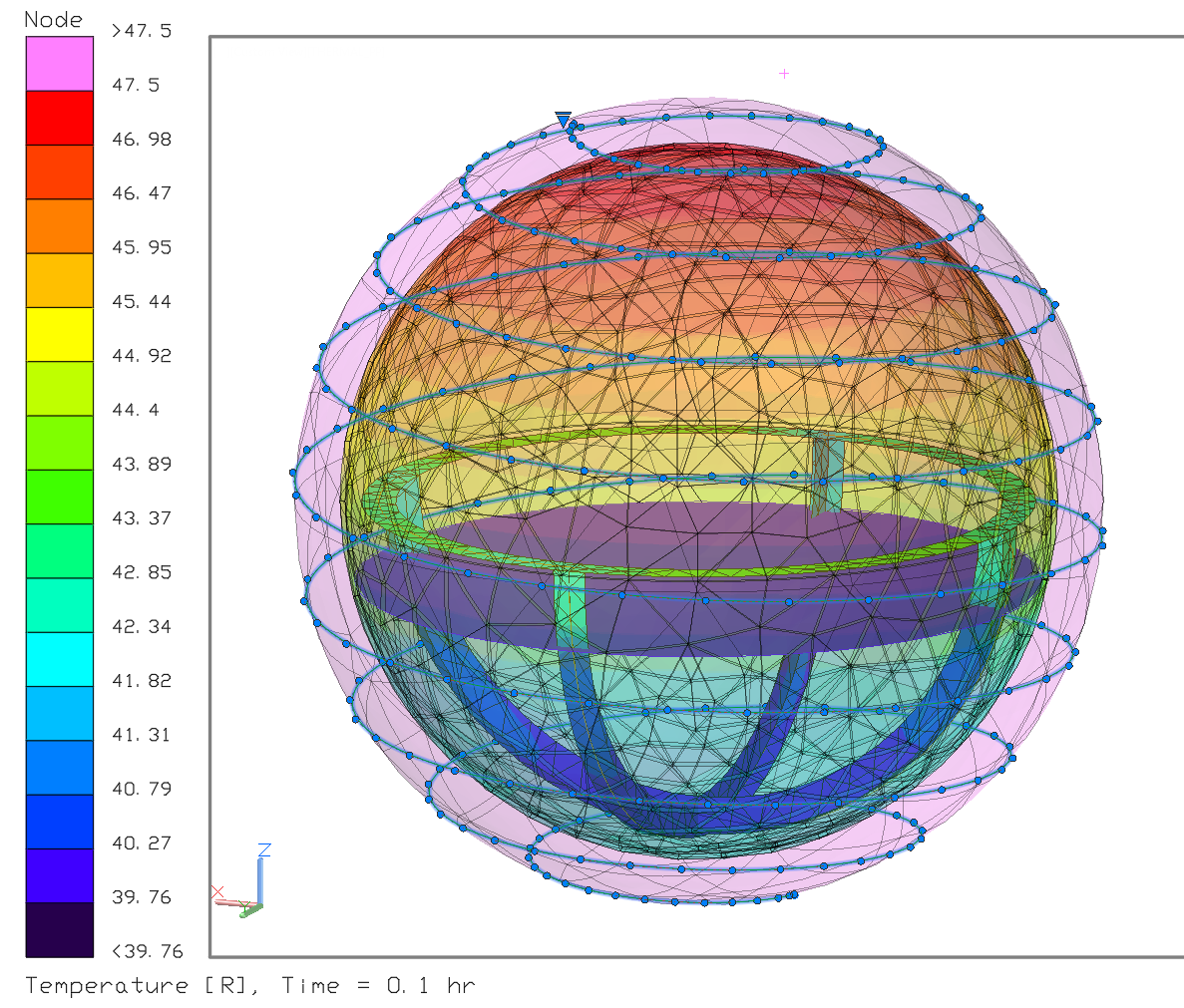

Thermal Stratification of a Cryogenic Tank

Is the tank half empty or half full?

Even optimists have a tough time predicting the pressure within a cryogenic tank, much less sizing pressurant bottles and designing pressure control systems based on complex transient scenarios. If the tank has been left long enough for thermal stratification to appear, it is also tough to predict the temperatures of extracted liquid even though this is often a critical parameter if you need to provide adequate subcooling for downstream pumps.

CFD tools can predict liquid positioning and slow recirculation in the nearly-stagnant ullage (vapor/pressurant) and liquid zones, especially for steady state solutions. They must often compromise thermodynamics (e.g., boiling, dissolution) and are too slow to simulate important transient events like fill, drain, and pressurization. Transient analysis of hours- or days-long stratification isn't feasible.

Flow network codes have difficulty with thermal stratification and with associated natural convection recirculation patterns.

CRTech has unique tools for modeling liquid-filled vessels, including treatment of the large uncertainties involved and all the important physics. We are continuing to develop new methods for handling the special needs of thermally stratified modeling, so check back for updates.

Long-term storage of liquid hydrogen using an internal heat exchanger and vapor-cooled shield

For more information and sample models, please visit our forum post on modeling stratified tanks.

See also: Marine and Aircraft Fuel Tanks, LNG Transport by Rail Car, Cryogenic Design